|

| September 18, 2018 | Volume 14 Issue 35 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Hydraulic accumulators in dual clutch transmissions get plastic pistons thanks to Freudenberg

Hydraulic accumulators provide improved energy efficiency by allowing manufacturers to install smaller hydraulic systems to actuate transmission gears. But their installation is complicated by the fact that the steel piston in the accumulator requires installation of an elaborate sealing package.

In response, Freudenberg Sealing Technologies has developed a new plastic piston that relies on single-part sealing technology and helps save energy and ease installation challenges in dual clutch transmission applications. The new piston eliminates three parts in the sealing package, thus making it easier to mount and lighter in weight.

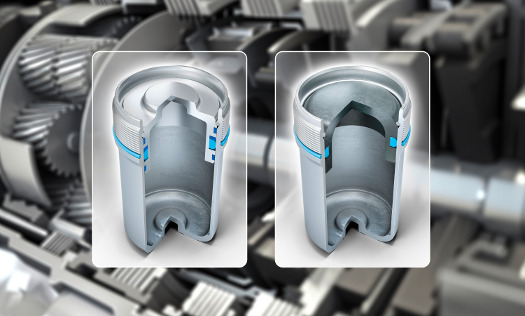

The new lightweight hydraulic accumulator for dual-clutch transmissions (depicted right) works with a simplified sealing system.

Dual clutch transmissions guarantee driving fun, whether they are used with classic internal combustion engines or in innovative hybrid powertrains. The gear change occurs without an interruption in tractive force. Hydraulic accumulators have been used for years to carry out the hydraulic activation of the gear actuator and to cushion peak hydraulic demand as efficiently as possible. They consist of a gas side and a liquid side, separated by a piston.

For example, as the hydraulic pump starts up when the lower pressure point is reached, the hydraulic accumulator takes in the hydraulic fluid that becomes available, and the gas -- nitrogen in this case -- is compressed, storing energy. When the pressure declines, the gas spreads out and forces the hydraulic fluid into the transmission circuit or to the actuators, depending on the driving situation. The hydraulic pump as well as the electric motor can be made smaller with this approach. A system with a hydraulic accumulator only needs about one-sixth the energy of a traditional, constantly operating pump. Freudenberg Sealing Technologies' development of its new plastic piston is a game-changer.

A plastic piston replaces the steel piston that has been used until now. Steel pistons are produced in a forming process and equipped with an elaborate sealing package that includes two guide rings that ensure the necessary slide properties. In addition, the actual piston ring must be secured with an additional back-up ring that blocks the seal's gap extrusion between the piston and the housing. By comparison, the new plastic piston, which is produced in an injection molding process, only requires one seal ring to be mounted.

The two guide rings that promote a sliding effect are eliminated in the design. Freudenberg Sealing Technologies' material specialists have chosen a material for the piston that exhibits the right slide characteristics between the piston and the housing. They also adjusted the material's thermal properties, allowing a much smaller gap between the piston and the housing and eliminating the need for the back-up ring that prevents seal extrusion. With this change in materials, it is possible to cut the piston's weight roughly in half. Since fewer components are now used in the installation of a hydraulic accumulator, the procedure can be greatly simplified. This increases the reliability of the production process.

Freudenberg Sealing Technologies' engineers also had to resolve another significant challenge: finding a plastic for the piston that was nearly as gas-tight as the steel that was being used. The solution is a thermosetting composite material that is impermeable to gas. Additionally, the material had to resist the entry of transmission oil and hydraulic fluid, exhibit an appropriate expansion coefficient at high temperatures, and offer the slide characteristics that the sealing system needed. There are tremendous demands on the material as well: The piston seal in a hydraulic accumulator must withstand several million operating cycles. With a special seal geometry, the engineers guaranteed long operating lives -- even under severe loads and temperature cycles.

Working with a German car manufacturer, Freudenberg Sealing Technologies is continuing to develop its hydraulic accumulators with plastic pistons, gearing them for use in a series-production hybrid vehicle. In extensive test stand trials and test drives, the technology has already shown the maturity it will need on the road.

Source: Freudenberg Sealing Technologies

Published September 2018

Rate this article

View our terms of use and privacy policy